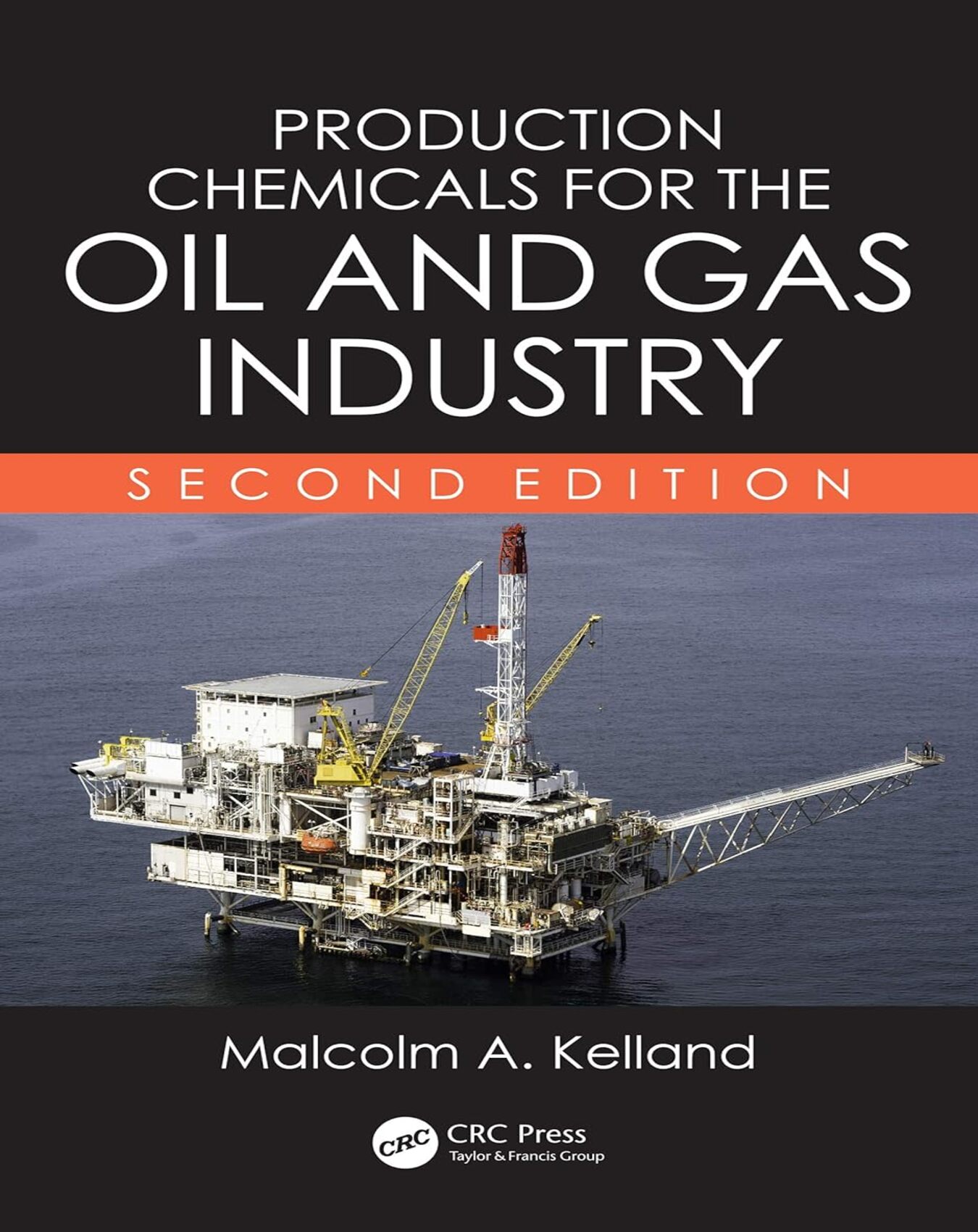

Production Chemicals for the Oil and Gas Industry, Second Edition by Malcolm A. Kelland is a comprehensive guide on the various chemical additives used in the oil and gas industry to address production chemistry issues. This book is essential for professionals involved in oilfield production as it provides in-depth knowledge of chemical structures, environmental considerations, and practical applications.

Key Features

- Extensive Coverage of Chemical Additives:

- The book reviews a wide array of production chemicals used in both onshore and offshore operations.

- It includes details on the structural classes of chemicals and their specific applications.

- Problem-Solution Approach:

- Each chapter begins by introducing a specific production problem, such as scale or corrosion, and discusses both chemical and non-chemical methods to address it.

- This methodical approach helps readers understand the context and the necessity of various chemicals.

- Environmental Considerations:

- The book addresses environmental and ecotoxicological regulations, such as OSPAR, REACH, and US environmental regulations.

- It emphasizes the design of greener chemicals that reduce toxicity, bioaccumulation, and enhance biodegradability.

- Practical Application:

- Practical aspects of chemical deployment, such as where to inject chemicals and their compatibility with production systems, are thoroughly discussed.

- The book includes numerous references from difficult-to-obtain sources, such as SPE papers and patents, making it a valuable resource for research and development.

Detailed Content Analysis

Chapter 1: Introduction and Environmental Issues

- Overview of production chemistry.

- Factors affecting the choice of production chemicals, including injection methods and chemical compatibility.

- Environmental regulations and the design of greener chemicals.

Chapter 2: Water and Gas Control

- Methods for controlling water and gas production using resins, gels, and polymers.

- Techniques such as in-situ monomer polymerization and the use of microparticles for water control.

Chapter 3: Scale Control

- Types of scales (e.g., calcium carbonate, sulfate, sulfide).

- Methods of scale inhibition and removal, including the use of polyphosphates, phosphonates, and biodegradable polycarboxylates.

Chapter 4: Asphaltene Control

- Use of asphaltene dispersants and inhibitors to manage asphaltene deposition.

- Structural classes of dispersants and inhibitors, including nonpolymeric surfactants and polymeric inhibitors.

Chapter 5: Acid Stimulation

- Techniques for acidizing carbonate and sandstone formations.

- Use of acids and acidizing additives, such as corrosion inhibitors and iron control agents.

Chapter 6: Sand Control

- Chemical methods for sand control, including resin and organosilane consolidation.

Chapter 7: Control of Naphthenate and Other Carboxylate Fouling

- Methods to prevent naphthenate deposition, including the use of acids and low-dosage inhibitors.

Chapter 8: Corrosion Control during Production

- Methods of corrosion control, including the use of film-forming corrosion inhibitors.

- Efforts to develop environmentally friendly corrosion inhibitors.

Chapter 9: Gas Hydrate Control

- Prevention of hydrate plugging using thermodynamic and kinetic hydrate inhibitors.

Conclusion

Production Chemicals for the Oil and Gas Industry, Second Edition is an invaluable resource for anyone involved in the oil and gas industry, particularly in the areas of production chemistry and chemical engineering. The book’s structured approach to problem-solving, extensive references, and emphasis on environmental considerations make it a critical addition to both professional and academic libraries.

However can be confusing and dull at parts. I have a petroleum engineering degree and was able to understand most of it. Some parts I had to do some clarification.

Not perfect but definitely a good book for people who need to learn about oilfield chemicals. Good as a reference guide.